Broilerzoom

What can it do?

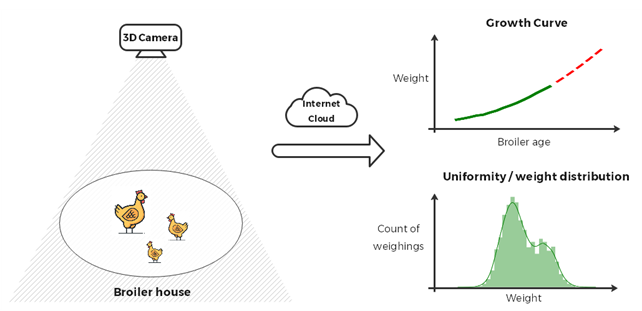

- Present real-time data on a web platform

- Measure both daily growth and flock uniformity

The need for accurate weighings

The broiler weight is the single most important parameter in broiler production and processing. Knowledge of the exact broiler weights in real-time during production would enable both daily management decisions at farm-level and across the whole value chain from feed mill to the slaughterhouse and beyond.

Even though the weight is so important, the weights of the individual birds are very uncertain during the production period. Traditional electronic scales are known to only measure a few birds of the flock and does not represent the whole flock. Only at processing time, the weight of dead birds are exactly measured – imagine a factory line where you would only measure the output! This would never happen.

BroilerZoom is a novel innovation from Animoni that measures broiler weight in real-time with a 3D camera-based solution. One of the great advantages is its ability to measure a very broad selection of the flock since it can monitor all birds below the camera. Therefore, it can deliver precise average flock weights and measurements of uniformity [Ref. 1].

The BroilerZoom is a real-time online solution where the user can analyze the weighing data on a website to make better decisions in the daily management or get new insights into the production.

New features are continuously being developed for the BroilerZoom. In the same way that a good farmer can see how the birds are doing – simply from looking, our camera platform offers many new opportunities for measuring the well-being and performance of the birds. For instance, dead birds or density of birds can be measured. Similarly, the activity and posture of the birds are closely related to thermal comfort and eating/drinking behaviour and can be used together with other data sources to give deep insights into the production.

How does it work ?

- The BroilerZoom units are installed at special locations within the house.

- Network connection is established.

- Website with growing curves and uniformity data is now accessible online in real-time.

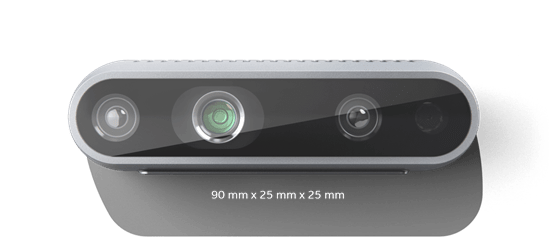

The technology

- 3D camera technology and clever algorithms.

- Each BroilerZoom unit has a built-in computer and networking.

- Algorithms developed from more than 20 million images with manual broiler weighings

The background

After working on related technology for several years in academia [Ref. 2], the founder of Animoni decided to invent a new, improved solution for weighing broilers. After two years of development and testing with a leading European integrator and independent farmers, the innovation is now ready to meet a larger audience.

The future

We want to deliver solutions which can monitor the performance, health and well-being of the individual birds. External sensors can measure, for instance, temperature and humidity of the surroundings. However, a good farmer can tell how the birds are really doing by watching – for instance, if they are too hot. Cameras can do the same – we want to be the farmers extra eye in the barn. The first step is measuring the most crucial parameter – weight. Afterwards, we are going to add new features that capture the full picture of the well-being and productivity of the birds.

Referencer

[Ref. 1] : The system has been evaluated in commercial broiler houses with a weighing accuracy in the range of 50-100g on individual birds during last week of rotation. Other types of poultry are still on experimental level.

[Ref. 2] : “Weight prediction of broiler chickens using 3D computer vision”, A.K. Mortensen, P. Lisouski and P. Ahrendt, Computers and Electronics in Engineering, Vol.123, April 2016, Pages 319-326